Have you ever wondered how to enhance the safety of operating forklifts amidst both dry and wet environments? These conditions can pose significant hazards when obscured by the presence of oil, water, or spills. Additionally, traversing over gravel and uneven terrain can potentially lead to tip-overs. Within this article, we propose the utilization of two distinct forklift inspection checklists, designed to mitigate such risks.

According to the OSHA standard 29 CFR 1910.178(q)(7), mandatory forklift inspections are stipulated. However, the standard lacks specific guidelines on conducting proper inspections. It is essential to adhere to a dry and wet forklift inspection checklist, which should be completed daily before or after each work shift.

Forklift Inspection Checklist

Implementing a forklift inspection checklist is a proactive measure to prevent accidents stemming from wear and tear. The regular usage of this equipment in daily workplace operations and repetitive routines can have a significant impact. By prioritizing safety measures, you can foster a healthy and secure working environment for employees during forklift operations.

The subtle variations between dry and wet forklift inspections are highlighted below...

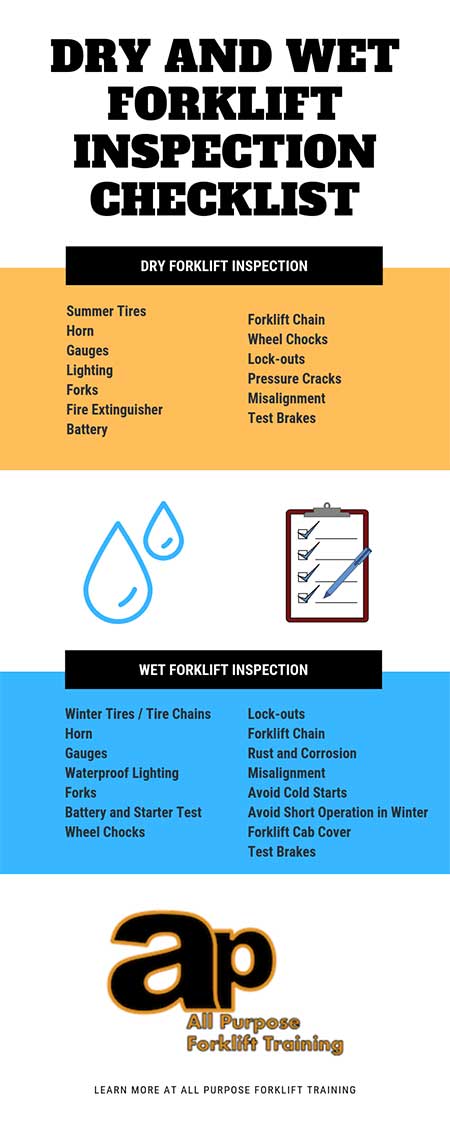

Dry Forklift Inspection Checklist:

- Summer Tires: Ensure appropriate tires are installed for optimal performance in dry conditions.

- Horn: Verify the functionality of the horn for effective communication and safety alerts.

- Gauges: Check and calibrate gauges to ensure accurate readings of essential parameters.

- Lighting: Inspect all lighting components to guarantee proper visibility during operation.

- Forks: Assess the condition of the forks for any signs of damage or wear that may compromise lifting capabilities.

- Fire Extinguisher: Confirm the presence and proper functioning of a fire extinguisher for immediate response to potential fire hazards.

- Battery: Examine the battery's condition, including charge levels and any signs of corrosion or damage.

- Grease Forklift Chain: Apply lubrication to the forklift chain to minimize friction and ensure smooth operation.

- Wheel Chocks: Securely place wheel chocks to prevent unintended movement when the forklift is parked.

- Lock-outs: Check lock-out mechanisms to prevent unauthorized use or accidental activation.

- Cracks: Inspect the forklift for any cracks or structural damage that may compromise its integrity.

- Misalignment: Ensure proper alignment of the forklift's components to prevent operational issues.

- Test Brakes: Conduct a thorough test of the brakes to verify their responsiveness and effectiveness.

By diligently following this dry forklift inspection checklist, you can enhance safety and minimize risks during operations in dry conditions.

Wet Forklift Inspection Checklist:

- Winter Tires / Tire Chains: Ensure proper tires or tire chains are installed to provide optimal traction in wet conditions.

- Horn: Verify the functionality of the horn for effective communication and safety alerts.

- Gauges: Check and calibrate gauges to ensure accurate readings of essential parameters.

- Waterproof Lighting: Inspect all lighting components to ensure they are waterproof and provide sufficient illumination in wet environments.

- Forks: Assess the condition of the forks for any signs of damage or wear that may affect lifting capabilities.

- Battery and Starter Test: Test the battery and starter system to ensure reliable performance in damp conditions.

- Wheel Chocks: Securely place wheel chocks to prevent unintended movement when the forklift is parked.

- Lock-outs: Check lock-out mechanisms to prevent unauthorized use or accidental activation.

- Forklift Chain: Inspect the forklift chain for proper lubrication and any signs of wear or damage.

- Rust and Corrosion: Check for any rust or corrosion on the forklift's components, addressing them promptly to prevent further damage.

- Cracks: Inspect the forklift for any cracks or structural damage that may compromise its integrity.

- Misalignment: Ensure proper alignment of the forklift's components to prevent operational issues.

- Avoid Cold Starts: Minimize cold starts by allowing the forklift to warm up properly before operation in wet and cold conditions.

- Avoid Short Operation in the Winter: Limit short operation periods in winter to avoid potential issues caused by temperature fluctuations.

- Forklift Cab Cover: Consider using a cover to protect the forklift's cab from water ingress during wet weather.

- Test Brakes: Conduct a thorough test of the brakes to ensure their responsiveness and effectiveness in wet conditions.

By diligently following this wet forklift inspection checklist, you can enhance safety and mitigate risks during forklift operations in wet conditions.

Forklift Inspection Requirements

Ensuring thorough forklift inspection encompasses three essential requirements: a comprehensive visual inspection, an operational inspection, and meticulous documentation of all inspections conducted. Alarming statistics from OSHA reveal that forklift-related incidents contribute to an estimated 100,000 industrial injuries annually. Therefore, adhering to proper inspection protocols becomes paramount in safeguarding workplace safety.

Visual Inspection:

Conducting a meticulous visual inspection enables the identification of any damaged components on the forklift. This includes careful scrutiny for indicators such as pressure marks, dents, cracks, chips, or signs of wear and tear that exceed safety limits. By attentively assessing these visual cues, potential risks can be promptly detected and addressed to maintain a safe operating environment.

Mechanical Inspection:

Following the completion of the visual inspection, it is crucial for operators to proceed with a comprehensive mechanical inspection by starting the engine. During this operating inspection, the proper functioning of various controls must be thoroughly tested. Pay close attention to the accelerator linkage, inch control (if equipped), brakes, and steering. Assess the steering system for any abnormalities, ensuring it is neither excessively stiff nor excessively loose. By meticulously evaluating these mechanical aspects, operators can ascertain the optimal condition and performance of the forklift, thereby ensuring a safe and efficient operation.

Documentation of Inspections:

In addition to diligently conducting the dry and wet forklift inspections checklist on a daily basis, it is imperative to place equal importance on proper documentation. Failing to identify a safety condition that warrants a forklift to be taken out of service could have severe and even fatal consequences. By emphasizing comprehensive forklift safety training, operators can acquire the necessary knowledge to effectively identify potential hazards during inspections. Thorough documentation practices contribute to a systematic approach in ensuring compliance and maintaining a safe operating environment.

Forklift Winter Safety Hazards

Winter presents operators and employers with formidable challenges to overcome.

Be vigilant of the following 5 forklift winter hazards:

- Snow and ice accumulation that can impede movement and create hazardous conditions.

- Slippery surfaces caused by wetness, posing risks of accidents due to reduced traction.

- Extreme cold weather conditions that can affect the forklift's performance and stability.

- Limited visual visibility while operating the forklift due to weather-related factors.

- Regular daily check-ups for forklift maintenance, including topping off fluids, to ensure optimal functionality and prevent weather-related issues.

When it comes to storing a forklift, it is crucial to ensure that it is kept in a dry and indoor location. Furthermore, it is essential to utilize appropriate oils and lubricants specifically designed to withstand freezing temperatures to maximize their effectiveness. For diesel forklift fuel systems, incorporating fuel additives can prove beneficial. These additives not only help preserve the fuel for future use during storage but also serve as safeguards against freezing-related issues. By adhering to these practices, you can safeguard the forklift and maintain optimal performance even during challenging conditions.

Operator and Equipment Protection

Operator Protection:

To ensure operator safety during winter, it is crucial to prioritize proper attire. Equip operators with suitable outdoor gear designed for cold conditions. Operators should dress in warm layers of clothing, including a hat and gloves, to provide optimal protection against the chilling temperatures. By adhering to these guidelines, operators can maintain comfort and safeguard their well-being while performing their duties in wintry conditions.

Equipment Protection:

To mitigate the risk of slippery conditions, it is recommended to equip the equipment with pneumatic tires fitted with chains. This combination enhances traction and minimizes the chances of accidents caused by poor grip on surfaces. By adopting this proactive measure, you can enhance equipment safety and promote a secure working environment, even in challenging weather conditions.

Proper Maintenance:

Maintaining forklifts in optimal condition is paramount to ensure their reliable performance. It is essential to adhere to a regular maintenance schedule, including servicing the forklifts once a month, especially during winter. By prioritizing proper maintenance practices, you can enhance the longevity of the forklifts, maximize their efficiency, and promote a safe working environment.

If you're seeking to become a certified forklift trainer or aiming to advance your career in this field, we offer comprehensive instructor courses conveniently available in your area. Explore our diverse range of forklift train the trainer programs, including those tailored for the crane and aerial lift industry. AP Safety Training has an all in one CAL OSHA training safety management program.

Ensure your skills remain up-to-date - if you need forklift renewal certification, our program offers the training required to refresh your expertise and maintain your certification, keeping you confident and compliant on the job.