Excessive wear and tear on forklift forks can decrease in-depth as time passes simply from ordinary wear and tear operations. In case the wear and tear to the forklift forks are under 10 percent of the whole thickness nonetheless, it's considered excessive wear.

Forks must be replaced, once forklift forks show unusual wear and tear and under a specific percent of thickness.

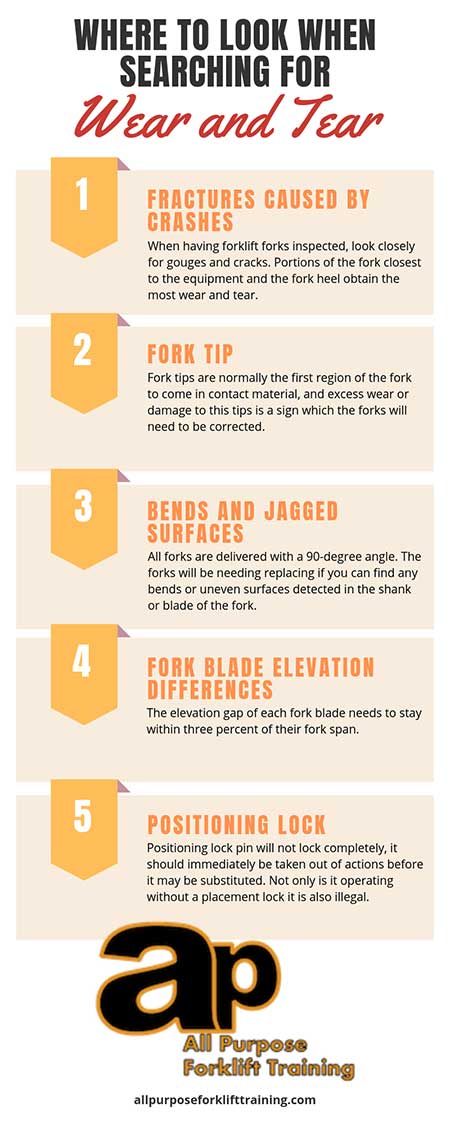

Fractures caused by crashes

When having forklift forks inspected, look closely for gouges and cracks. Portions of the fork closest to the equipment and the fork heel obtain the most wear and also gouges and fractures are signs a fork have to be corrected.

Fork tip

Fork tips are normally the first region of the fork to come in contact material, and excess wear or damage to this tips is a sign which the forks will need to be corrected.

Bends and jagged surfaces

All forks are delivered with a 90-degree angle. The forks will be needing replacing if you can find any bends or uneven surfaces detected in the shank or blade of the fork.

Fork blade elevation differences

The elevation gap of each fork blade needs to stay within three percent of their fork span. As an example, when the forks are 42 inches long, the allowable difference in the fork elevation would be 1.26 inches, and any gap in fork elevation beyond 1.26 inches is an indication that both forks should be replaced.

Looking to enhance your skills? Get forklift classes that provide hands-on training and certification, opening doors to exciting job opportunities in the field of material handling.

A couple of notable indications that the fork hooks need to be substituted are filthy, yanking, noticeable wear or different deformities. Along with those, the pins should be replaced in the event the wear to the hook is causing an inordinate quantity of space between the carriage and the fork.

Positioning lock

Positioning lock pin will not lock completely, it should immediately be taken out of actions before it may be substituted. Not only is it operating without a placement lock it is also illegal.

Questions to ask when getting ready to restore forks

If they should be replaced in pairs?

A common question that's asked is whether or not forks need to be replaced singularly or in pairs. While the wear tear and damage may be apparent on one fork, it isn't safe to replace them one at a time. Experts advise replacing forks to guarantee they are both currently working.

Are custom fixes or alterations to the forks okay?

Pros recommend seeking expert help when it comes to repairs and alterations. This makes sure that safety standards will be met by the forks and that the project is done.

How is replacement fork caliber determined?

When forks are made out of high excellent boron-carbon alloy high strength steel, and they have been rated 20 percent stronger than those made with 40CR. In addition, forks fully put in heating ovens and cooling pools are shown to be the most lasting. Forks that are top quality meet or should exceed all of ANSI/ITSDF and ISO standards.

Need a forklift training school near you? Contact us today for our forklift certification and instructor training locations in your area. Give us a call Toll-Free at (888) 501-1355. Questions and prices at no cost. Forklift classes fill fast!